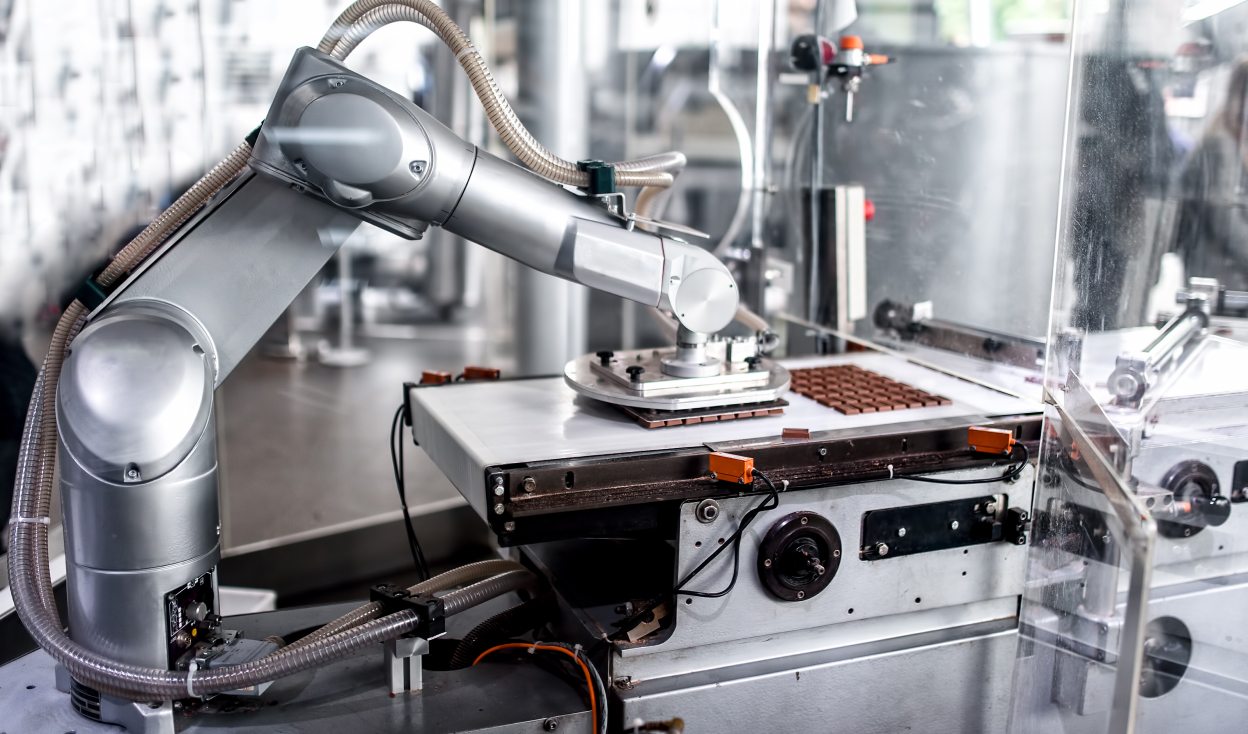

Automated quality control is playing an increasingly important role in industry, enabling automatic inspection and detection of defects in products. The systems use vision technologies such as cameras, image analysis software and artificial intelligence algorithms to accurately assess the quality and compliance of products with specific standards.

As part of the delivered application solutions, we support our clients:

- defect detection – automatic scanning of products for defects such as cracks, scratches, uneven surfaces, mismatches;

- dimension and geometry control – measurement of length, width, thickness, angles, radii, etc.

- sorting and classification based on specific quality parameters to identify quality defects and automatically sort products into different categories, such as “meeting the requirements”, “for repair” or “rejected”. This enables effective production quality management;

- barcode readers and identification of barcodes, serial numbers, product identifiers, etc. Automatic validation of codes, as well as identification and tracking of products in the production process;

- elimination of defects and reduction of rejects – defective products can be detected and removed at an early stage of production, which contributes to increasing efficiency and reducing costs.

Designing and automating solutions for industry

Looking into the future and observing the development of technology, we invest in improving the team’s qualifications and expand the areas of specialization in the field of structural engineering, control systems and robotics.

Solutions

for industry

for industry

Experience

engineers

engineers

Many areas

of specialization

of specialization

Functional

ideas

ideas

48 690 22 88 77

48 690 22 88 77  kontakt@appcott.pl

kontakt@appcott.pl